|

OSCILLATING SEALS - The inner or outer member of the

assembly moves in an arc relative to the other, rotating one

of the members in relation to the O-Ring. Sealing can be

complicated by the fact that the O-Ring can snake or bunch in

the gland. The relative motion of the moving part to the fixed

part tries to carry its O-Ring contact with it, distorting the

rubber circumferentially. Many oscillating seals utilize

standard reciprocating design parameters or slight

modifications to reduce friction.

ROTARY SEALS - Rotary seals are where an inner or

outer member of the sealing assembly revolves around the shaft

axis in only one direction. The direction may be reversed.

Should there be multiple brief arcs of motion, the designer

should refer to parameters for oscillating seals.

|

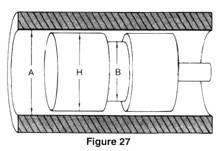

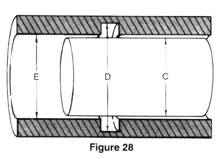

RECIPROCATING SEALS - These seals are designed much

like static radial seals except for dynamic applications the

squeeze is less likely to reduce friction and heat buildup.

There are two types of reciprocating seals - male or piston

gland design (Fig. 27) and female or rod gland design

(Fig. 28).

MALE or PISTON RECIPROCATING SEALS - The design

parameters for this type of seal are as follows:

Bore dimension (A)

Piston Dimension (H)

Groove

Dimension (B)

Groove Width (G)

FEMALE or ROD RECIPROCATING SEALS - The design

parameters include the following:

Bore dimension (e)

Rod Dimension (C)

Groove Dimension

(D)

Groove Width (G)

|